Home » Industries »

Automotive industry

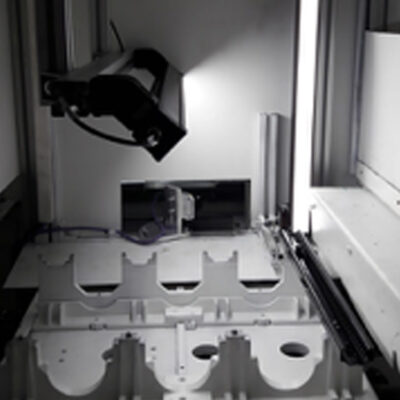

The automotive industry, in which robotization is developing particularly rapidly, is also one of the industries in which the quality of the final product is very much emphasized. A quality defect has consequences in the form of customer complaints and affects safety. It is in this industry that we have many implementations of vision control systems.

Main advantages of this form of quality control:

- quality control in the production cycle,

- bypassing the laboratory,

- shorter quality control time ,

- 100% components inspected.

Examples of completed projects in the automotive industry:

- integration of the data registration system on presses with the department-wide database

- visual inspection system on the lines of automatic assembly of car guides,

- visual inspection system of internal dimensions of the product,

- a vision system for detecting the profile’s central flange at a vision control station on the production line,

- visual inspection systems for injector components: fittings, pintle, upper housing, etc.

- a vision system for measuring laser welds in the laboratory,

- visual control system for the presence of Flux fluid on a PCB,

- robotic soldering station equipped with a vision system to control the correct placement of wires and the presence of solder,

- position of visual quality control of engine stators,

- CMT weld vision inspection system,

- DM code vision control system.