Home » Industries »

Food and Beverage industry

Food producers are required to produce products with strictly defined, consistent properties and compositions. Therefore, modern production management systems in the food industry should include access to real-time and historical process data; full automation of production and storage, monitoring of production media and visual quality control. All these elements influence the production efficiency. Monitoring of individual stages of production is a guarantee of maintaining the quality of the final product.

Modern solutions for obtaining data from production, reporting, archiving production data or e-mail / SMS alerts are tools supporting the Maintenance and Quality Departments, Production Directors. PRO-CONTROL has been supporting food industry companies in modernizing production lines and automating production processes for many years. Our clients include bakeries, beverages and sweets producers, and cured meat producers.

Examples of completed projects in industrial automation in the food industry include:

- MES class systems – expansion of the production support system and monitoring of effectiveness on the confectionery production line

- monitoring of production media – visual inspection of the correct closure of packaging

- modernization of vision control systems

- visual inspection of printing on packaging

- automatic bagging station for rolls to collective cartons

- computer kitchen monitoring system

- production line automation – dosing control system

- modernization and replacement of the control system

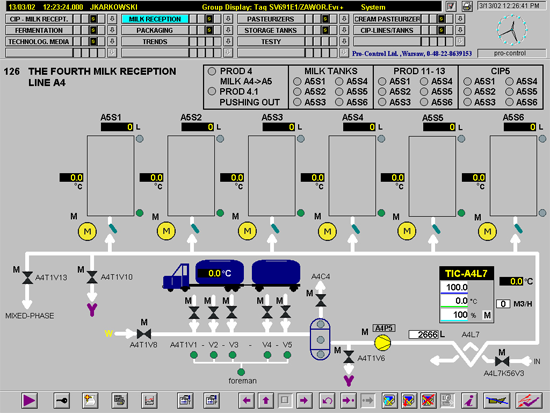

- production control and visualization system

- replacement of the operator panel in the Siemens PCS7 system

- modernization of automatic silo filling and unloading

- modernization of the rectification installation

- migration of reporting systems

- introduction of anti-pressure safeguards

- modernization of the control system, including:

- adaptation of the Trans 2 drivers to communication with the MES system,

- adjusting the PMT2 driver for communication with the label printer,

- modification and extension of three SIMATIC S7 drivers and operator panels.

- InTouch visualization system migration from version 7.1 to version 9.0

- migration of the SIMATIC S5 system to Rockwell Automation Logix