Home » Industries »

Sugar industry

Pro-Control has completed dozens of industrial automation projects in the sugar industry, from improving technological processes to comprehensive modernization and expansion of sugar factories. We carried out projects in Poland, Spain, Russia, Kazakhstan, Belarus, Ukraine and Latvia.

We have a specialized group of engineers handling projects for the sugar industry. The benefits of introducing modern industrial automation and control solutions are reflected in costs and profits through:

- monitoring of pressure and thermal parameters

- duration of individual production stages, energy consumption

- the degree of use of OEE machines

- monitoring of production media

- water consumption, energy resources

- easy diagnostics of failures, preview of key parameters for maintenance and production managers

- increasing the productivity of the sugar factory, improving the quality of sugar (purity, color)

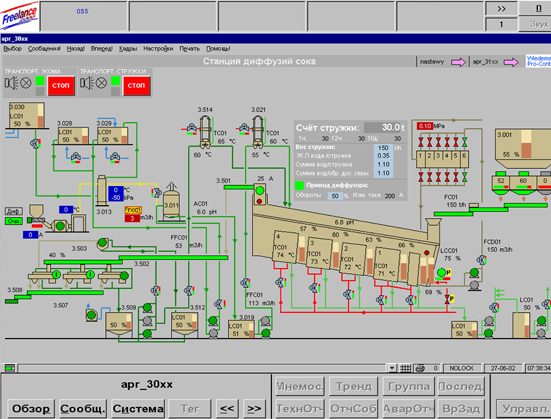

Measured values, set parameters, balance values, or important alarms – these are only selected key information that can be presented in the form of synoptic and archived (trends).

Selected projects made by Pro-Control in the sugar industry:

- Modernization and expansion of sugar plants for the processing of 11.5 thousand. tonnes per day – application of a comprehensive automation system and metering of all important installation locations, full control of the assumed technological and production parameters

- Modernization of the dryer automation system based on ABB’s DCS

- Comprehensive automation of sugar factories and raw sugar refineries

- Modification of the production control system in the field of data exchange, visualization and archiving

- Delivery and replacement of frequency converters

- Modification of the product control system in terms of communication after PROFIBUS DP of sugar scopes with the Freelance system

- Combination of the Freelance system with the Crystobserver / ITECA SOCADEI system for the analysis and monitoring of sugar crystals in the cooker

- Modernization of sugar factories and packing plants

- Automatic diabetes cooking program of the cooker II and III

- Control and visualization of 4 plate heaters in the defecation juice heating station

- Project and software change for sugar packing stations – functionality extension with sugar segregation

- Project and program for automatic cooking of hereditary diabetes – 60t cooker with an inverter controlled agitator, including supplies: control cabinet with AC800FR ABB redundant driver, modular cabinet (S800 ABB modules)

- Automation system for the production of cold crystalline and inherited diabetes

- Modernization of heaters and upgrade of the Freelance system

- Project and prefabrication of control cabinets and inverter boilers B and C, modification of the Freelance system software and commissioning of the control system for boilers

- Renovation of power supply and control cabinets of the boilers

- Automation of the pulp drying room and the sampling point

- Visualization and automation environment for AB centrifuges as well as control and visualization of steam valves on boilers

- Control and power system for biogas plants in a sugar factory

- Comprehensive modernization of the sugar factory

- electrical industry: project, assembly supervision, commissioning, lighting

- AKPiA industry: project, development of control and regulation algorithms, software

- development, completion of deliveries, fabrication of prefabricated elements, field assembly, assembly supervision and commissioning.

- Modernization of the control software of the Kawasaki ZD130 palletizing robot and the software of the pulp drying plant

- Comprehensive modernization of the sugar factory.