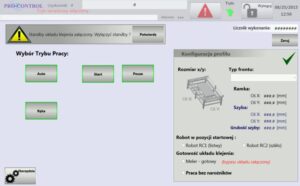

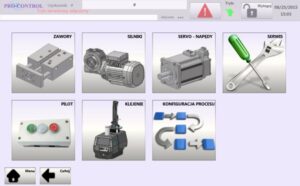

In 2014, PRO-CONTROL designed a complete control system, software, and electrical equipment for automated manufacturing cell for the bonding of aluminum furniture fronts.

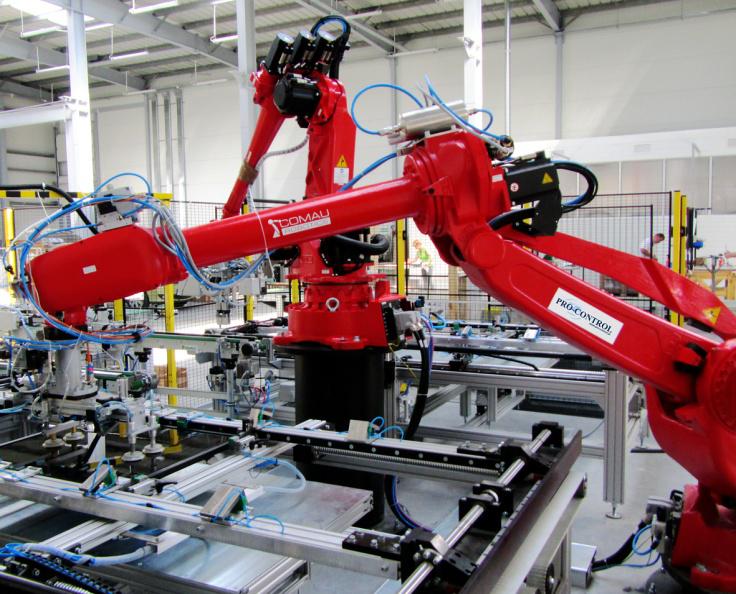

The stand has been implemented in a modern furniture factory. The entire process of profile assembly automation was based on the popular COMAU industrial robots – SMART NJ110 3.0 and SMART NJ40 2.5.

Integrated with the C5G controller and wired panel, these robots are the ideal solution for palletizing and handling applications. A very important point of the task was the appropriate selection of the glue and glue system made in cooperation with the world’s leading glue producers. The next stages were the preparation of the design of the control and electrical system, the production of mechanical parts and their assembly at the target furniture factory. The project assumed complete elimination of fasteners such as corner plates, additional profiles, screws, etc.

The furniture fronts folding station consists of the following elements:

- reservoir of long and short profiles,

- 2 manipulators for collecting profiles from bins,

- adhesive system with dosing heads,

- COMAU robot – SMART NJ40 2.5 with a lifting capacity of 40 kg for transferring profiles,

- COMAU robot – SMART NJ110 3.0 with a lifting capacity of 110 kg for transporting windows and ready fronts,

- 2 assembly tables for ready profiles,

- 2 corner application stations,

- finished product buffer.